KOBAYASHI's Technology/Product

KOBAYASHI INDUSTRIAL specializes in integrated production of mechanical

parts including transportation equipment parts such as motorcycle and motor vehicles.

We can also contribute to shortening delivery time and cost by integrally

manufacturing products of complicated processing combination through our

own company without going through other companies.

Please also consult us about complicated shapes and processing parts development.

Please also consult us about complicated shapes and processing parts development.

HOME

> KOBAYASHI's Technology/Product

> Mold / Jig

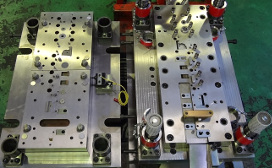

Mold / Jig

Progressive press mold

Welding jig

Inspection jig

HOME

> KOBAYASHI's Technology/Product

> Press working

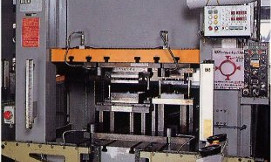

Press working

Shaving

Half pierce & trim processing

Thick thickness

increase processing

High tension material

press drawing

Press thick plate processing

HOME

> KOBAYASHI's Technology/Product

> Cutting / Grinding

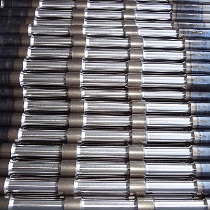

Cutting / Grinding

Broaching

Serration rolling process

Gear cutting

Polishing processing

Shaft / Lace machining

HOME

> KOBAYASHI's Technology/Product

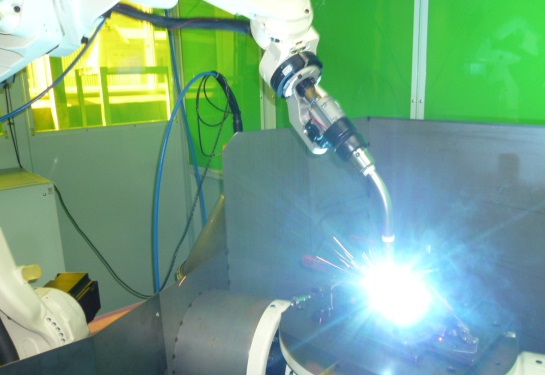

> Welding

Welding

Welding:

Frame parts

Welding:

Frame parts

Welding:

Suspension parts

Welding & assembly:

Steering parts

HOME

> KOBAYASHI's Technology/Product

> Assembly / Inspection

Assembly / Inspection

Assembly:

Suspension parts

Assembly:

Shift lever parts

Assembly:

pedal (composite material)

Assembly:

Shift shaft parts

HOME

> KOBAYASHI's Technology/Product

> Quality Control

Quality Control

CMM

CNC Vision

Measuring Systems

Shape Surface Roughness

Measurement

Amsler type

testing machine

Welding macro cut

assurance

HOME

> KOBAYASHI's Technology/Product

> Main Equipment

Main Equipment

Cutting and Grinding

NAME

ABILITY

NUMBER

NC LATHE

8inches/6inches

7

MACHINING CENTER

BT40

2

TAPPING CENTER

BT30

2

TURNING CENTER

∼Φ35

3

GEAR CUTTING MACHINE

5

ROLLING MACHINE

15t 16t

2

NORMAL LATHE

8inches/6inches

2

VERTICAL MILLER

2

NC OPERATION MILLER

2

BROACHING MACHINE

4t STROKE 800mm

2

VARIOUS DRILLING MACHINE

14

HIGH-SPEED CUTTING MACHINE

1

CENTERLESS GRINDER

3

CYLINDRICAL GRINDER

4

SURFACE GRINDER

2

CONTOUR MACHINE

2

Press working

NAME

ABILITY

NUMBER

500t

2

300t

2

200t

2

200t Progressive(servo)

1

150t

4

CRANK PRESS

150t wide

1

110t

1

80t

1

45t

1

35t

1

HYDRAULIC PRESS

10t

2

1t

1

PRESS BRAKE

80t(servo)

1

SHEARING

1200mm

1

RIVETING MACHINE

0.7 - 1.5t

7

Welding

NAME

ABILITY

NUMBER

SEMIAUTOMATIC WELDING MACHINE

DIVISION WELDING, CIRCUMFERENCE

6

ROBOT WELDING MACHINE

SYNCHROMOTION

11

MANUAL WELDING MACHINE

CO2 ARGON GAS

4

ARC WELDING MACHINE

1

TIG WELDING MACHINE

1

PLASMA CUTTING MACHINE

1

Other equipments

NAME

ABILITY

NUMBER

WIRE ELECTRIC SPARK MACHINE

a-1iA,

a-0iB

2

SPARK DRILLING MACHINE

JEM-350

1

CO ORDINATE MEASURING MACHINE

Crysta-ApexC

1

STRENGTH TESTER

20t

1

HARDNESS TESTER

ROCKWELL

1

SURFACE ROUGHNESS TESTER

FTA-S4D3000-D

1

CNC IMAGE MEASURING INSTRUMENT

QV Apex 404

1

FILM THICKNESS METER

1

PROJECTOR

1

HOT-AIR DRYING FURNACE

1

WASHER

1

OVERHEAD TRAVELLING CRANE

1t - 2.8t

6

TERMINALS FOR PRODUCTION CONTROL SYSTEM

26

3D-CAD

2

As of December 01, 2022

Contact us

Contact us +81-(0)53-441-2871

+81-(0)53-441-2871 JAPANESE

JAPANESE HOME

HOME

Mold/Jig

Mold/Jig